- Via dell'industria 5, Castel d'Ario (MN) Italy

- export@mtrcaldaie.com

- +39 0376 150 5872

- +39 0376 150 5872

Cl-En PLUS

CL-EN PLUS: INDUSTRIAL BOILER FOR BURNER PELLET

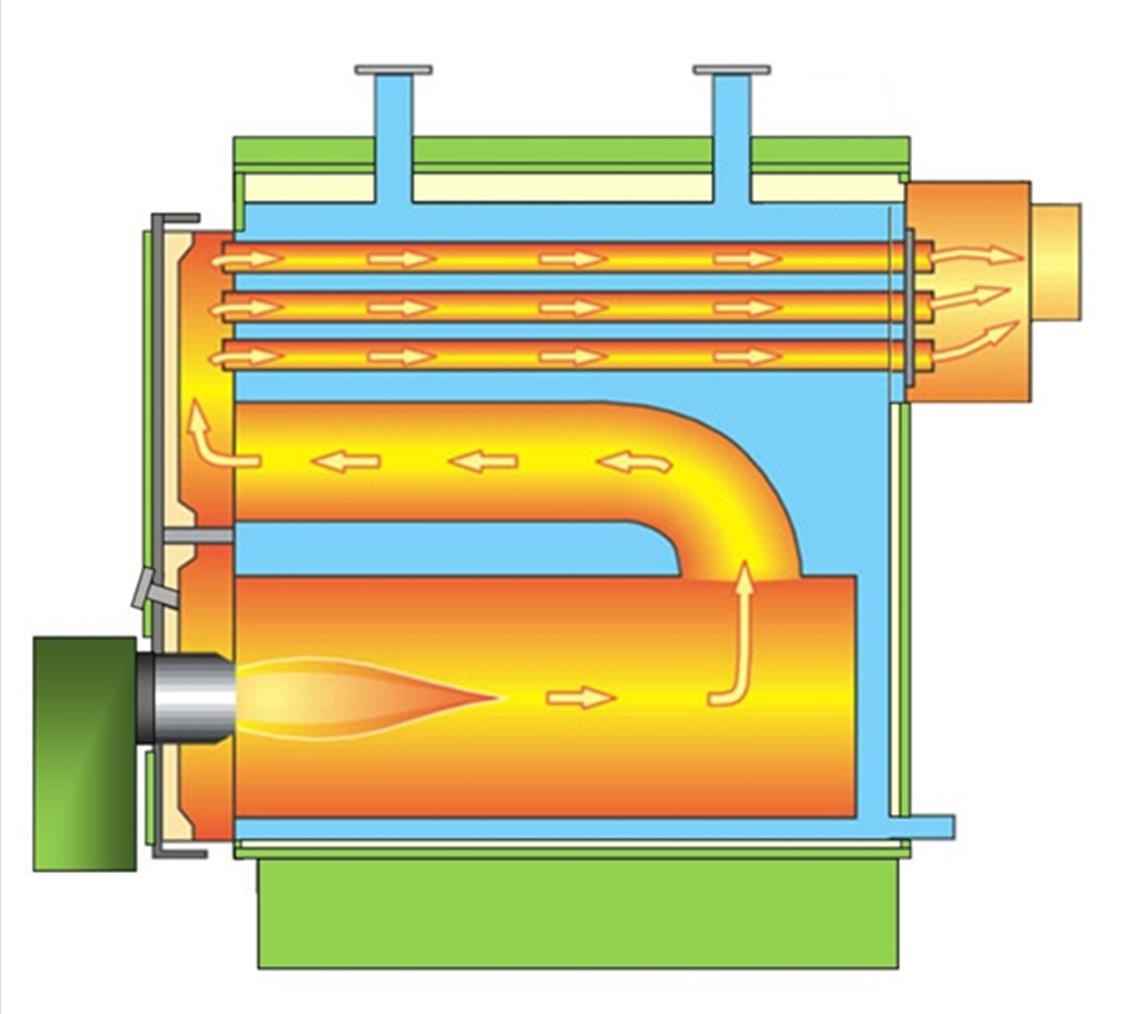

CONSTRUCTION TECHNOLOGY

The generator is monobloc, in three passes with actual flame passing, pressurized combustion. The technology in three passes with flame passing reduces the residence time of the combustion gases in high temperature areas.

The property to "narrow" width solves the unique needs of installation and introduction in thermal power plants with a reduced size.

PRINCIPLE OF OPERATION

BODY BOILER

- The shell is made of high quality metal and is welded at full penetration.

- The combustion chamber is cylindrical, internally and externally welded to the front plate and the rear closed with bottom completely wet.

- The smoking pipes are welded to the tube plates arranged above the combustion chamber. Their arrangement is

been designed to optimize the circulation. Are also protruding from the rear plate to raise the

temperature of the weld bead, avoiding the formation of acid condensation on the same. ATTACKS

ATTACKS

- A diaphragm inserted inside the boiler body allows optimum circulation of water: the temperature inside is uniform and therefore the formation of deposits is contained.

- At the top of the generator are planned attacks and water supply and return connection for the connection to the expansion tank.

- In the lower part is provided for the attack for the discharge sludge.

- The front plate is equipped with provision for grounding.

- Attacks of water supply and return are flanged, complete with flanges, bolts and gaskets.

SMOKE REAR CAMERA

- The rear smoke chamber, made of sheet steel is complete with seal, horizontal attack without flange for the discharge of fumes, cleaning door, and attack for the discharge of flue gas condensate.

FRONT DOOR

- The front door, openable from both sides by hinges is steel internally lined with insulating insulating / refractory material, provided with seal and blanking plate for attachment of the burner and indicator for the control of the flame.

COAT

- The coating of the boiler body is made of mineral wool 80 mm thick.

- The external protection is given by panels of painted galvanized steel covering the boiler body and the tailgate.

SAFETY

Inside the boiler, immersed directly into the generator, there is a heat exchanger which, when connected to a temperature relief valve (optional), when you arrive at high temperature (95 ° C - 98 ° C), cold water from the water and shows the temperature at optimum levels.

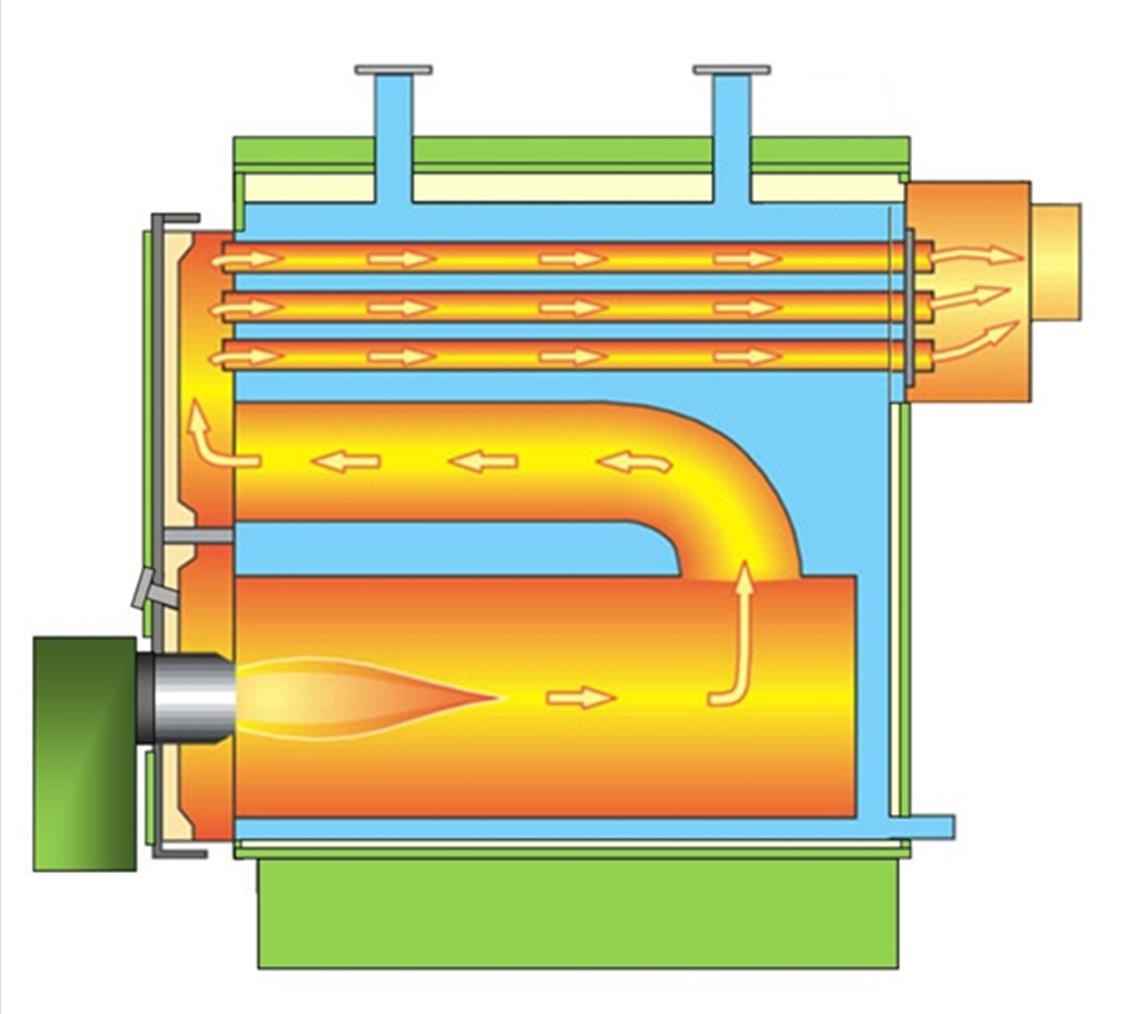

CONSTRUCTION TECHNOLOGY

The generator is monobloc, in three passes with actual flame passing, pressurized combustion. The technology in three passes with flame passing reduces the residence time of the combustion gases in high temperature areas.

The property to "narrow" width solves the unique needs of installation and introduction in thermal power plants with a reduced size.

PRINCIPLE OF OPERATION

BODY BOILER

- The shell is made of high quality metal and is welded at full penetration.

- The combustion chamber is cylindrical, internally and externally welded to the front plate and the rear closed with bottom completely wet.

- The smoking pipes are welded to the tube plates arranged above the combustion chamber. Their arrangement is

been designed to optimize the circulation. Are also protruding from the rear plate to raise the

temperature of the weld bead, avoiding the formation of acid condensation on the same.

- A diaphragm inserted inside the boiler body allows optimum circulation of water: the temperature inside is uniform and therefore the formation of deposits is contained.

- At the top of the generator are planned attacks and water supply and return connection for the connection to the expansion tank.

- In the lower part is provided for the attack for the discharge sludge.

- The front plate is equipped with provision for grounding.

- Attacks of water supply and return are flanged, complete with flanges, bolts and gaskets.

SMOKE REAR CAMERA

- The rear smoke chamber, made of sheet steel is complete with seal, horizontal attack without flange for the discharge of fumes, cleaning door, and attack for the discharge of flue gas condensate.

FRONT DOOR

- The front door, openable from both sides by hinges is steel internally lined with insulating insulating / refractory material, provided with seal and blanking plate for attachment of the burner and indicator for the control of the flame.

COAT

- The coating of the boiler body is made of mineral wool 80 mm thick.

- The external protection is given by panels of painted galvanized steel covering the boiler body and the tailgate.

SAFETY

Inside the boiler, immersed directly into the generator, there is a heat exchanger which, when connected to a temperature relief valve (optional), when you arrive at high temperature (95 ° C - 98 ° C), cold water from the water and shows the temperature at optimum levels.